| |

|

|

| |

IBM DC Connect has been at the core of enterprise data collection

solutions for over a decade. The platform was designed to provide

general purpose hardware connectivity for tracking labor and inventory

using barcodes and RF tags and badges. Since it's inception it has been

used in thousands of data collection solutions throughout the world.

It's simple and intuitive design has made it easy for IT personnel to

bring sophisticated data collection solutions on-line quickly. designed to provide

general purpose hardware connectivity for tracking labor and inventory

using barcodes and RF tags and badges. Since it's inception it has been

used in thousands of data collection solutions throughout the world.

It's simple and intuitive design has made it easy for IT personnel to

bring sophisticated data collection solutions on-line quickly.

Standard interfaces exist for the popular ERP systems such as; MAPICS,

JDE, SAP, and others. Development tools exist to rapidly create

custom templates. These templates feed the ERP system. Complete

applications exist to providing solutions such as time & attendance,

labor tracking/costing, production control/monitoring , inventory

warehouse management, automatic on-line conveyor scanning, scale weight

collection, on-demand barcode and label printing, security access,

bell control and more.

|

|

| |

|

|

| |

|

|

| |

The DC Connect client

has been adapted to a number of fixed and RF terminals. Terminals from

many different manufacturers are supported. Newer CE devices can be

integrated using DCNet.

|

|

| |

IBM 7526 |

Symbol 6846 |

|

| |

|

|

|

| |

Intermec 2835 |

Telxon 960SL |

|

| |

|

|

|

| |

IBM DC Connect for Windows XP provides the

software connection between the plant floor and management. The software is

an open platform designed to communicate with IBM 7526 data collection

terminals and Symbol 6846 and Intermec 2435 RF handhelds. RTG's DCNet

extends the terminals offering to include virtual any CE device.

DC Connect Client allows the user one common

interface independent of terminal type. The data collection programs

can be standardized across different terminals. Once the data collection

program is created they are stored in a folder and can be graphically

attached to the terminal function keys. Since the programs are downloaded to

the terminal, reliable real time data collection is distributed and not

dependent on the network. The user can create their own set of transaction

programs using the IBM development tool kit or choose from an existing

library of pre-built templates.

Plant Floor Connectivity has never been

easier with IBM DC Connection. Network administration terminal program

management and host connectivity are greatly simplified. You don't

have to be a programmer or network certified to manage plant floor

information with DC Connect. Existing legacy host software need not be

modified. ERP Bridge provides bi-directional keystroke mapping to your

existing AS-400 application. "So if you can type it in, ERP Bridge can

activate the process without modification to the existing host software."

For Windows XP applications, DC Connect is ODBC compliant, so data

can be exchanged through Microsoft compliant application payroll interfaces.

|

|

| |

|

|

| |

The configuration screens provide a graphical

intuitive environment for development of the prompts and data input

associated with each transaction. Each transaction is linked to a function

key. Templates are created by mapping the operation of each function key.

The templates are downloaded to each device. Loading the templates on each

device reduces network traffic and system reliability.

|

|

| |

|

|

| |

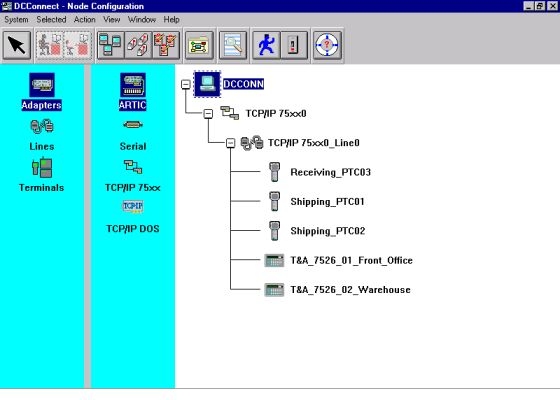

Network and terminal management are designed for easy use. An intuitive

graphical operator interface is provided. The terminal network is

portrayed using graphical icons. To configure the network devices, a

user need only select the appropriate adapters, communication lines, and

terminal types and then drop them into the appropriate schematic.

|

|

| |

|

|

| |

|

|

| |

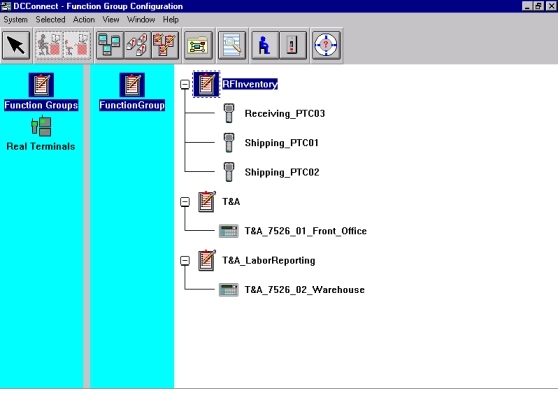

Terminals that use the same templates and perform

identical tasks are group together. This simplifies configuration by

reducing the interaction from each terminal to each group of terminals.

Selecting the group allows all changes to be adopted by each terminal in the

folder. Grouping organizes the terminals into manageable clusters of

devices.

|

|

| |

|

|

| |

|

|

| |

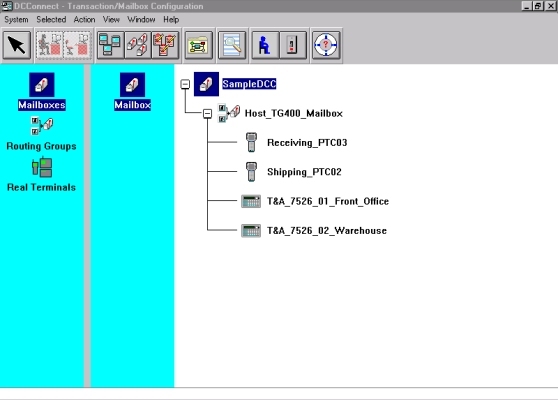

The data is placed in a data mail box to be

exported to the host or network application.

The data that is collected is

routed to a corresponding mailbox. Data collected in each mailbox is linked

to an application. Data can be passed to multiple applications across the

network.

|

|

| |

|

|

| |

|

|

| |

Ross Technologies Group is uniquely

positioned to provide integration services for IBM data collection

products. Our staff has over 15 years experience interfacing DC connect

and other leading data collection technologies. The best software

integrated with the best hardware to

provide the best solution.

Benefits include:

One software solution for all your

data collection requirements:

Time & Attendance, Inventory Control,

Labor Reporting

Asset Tracking, Receiving, and Quality Control

Start small and grow with IBM DC

Connect Server

Open Platform, Windows XP, Ethernet

or Serial Communication, Wired or wireless

Over a decade of experience providing

quality data collection solutions

Ross offers on-site and phone support, start-up assistance

& training

Easy to install, easy to maintain

solution

Call us to discuss your particular application

requirements!

|

|

|